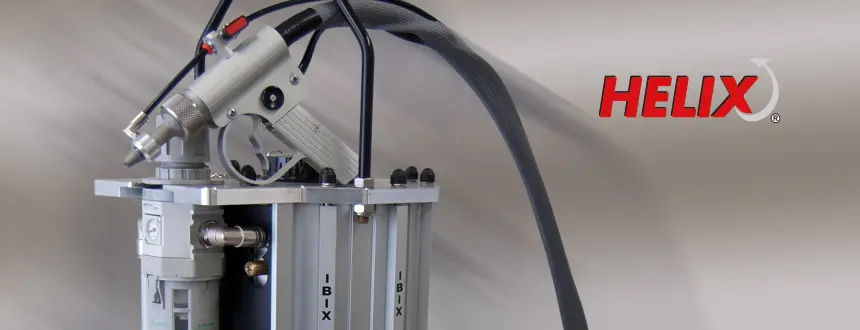

Helix is a special technology able to give a rotatory motion to the abrasive exiting the gun of the IBIX cleaning system.

In this way the impact of the abrasive on the surface is not vertical but tangential so that the abrasion is more gentle and respectful of the treated surface, increasing at the same time the contact area and the machine effectiveness.

The Helix gun reduces significantly the air flow necessary for the functioning of the micro aero-abrasive system and this allows to highlight the potentialities of IBIX devices, which have always been known for their small dimension, light weight, ecology and affordable price.

The Helix patent has been developed in particular for the restoration field and it is ideal for wood and all materials that need to be treated gently.

HELIX The first helical vortex cleaning system in Italy.

What does HELIX® Means ?

Compared to traditional nozzles the patented new-generation HELIX® system offers, for the same nozzle dimensions, an increased tangential contact area, maintaining the action of the media on a given surface. This makes it possible to increase the distance of the operator from the treated surface, minimising invasiveness without losing the regularity and evenness of cleaning and avoiding the need for operators to make constant corrections, which can result in definitive loss of the substrate being treated.

A winning innovation

The heart of the patented HELIX® system exploits a combination of the Venturi effect, generated by a special configuration of the outlet cone, with a device that induces a helical rotary movement, in order to considerably reduce the air volume required to operate the machine. This has made it possible to enhance the capacity of IBIX® equipment, which has always been known for its compact dimensions, lightness, low compressed air and media consumption, which, in addition to economic savings, leads to ease of operation on the worksite and extremely easy transport and handling. The use of special wear resistant steels and the absence of mechanical moving parts means that the new HELIX® nozzle stands out for its durability even when the use of very hard minerals like almandine garnet, corundum, etc. is necessary.

IBIX® DRY AND WET MICRO-AIR-ABRASION SYSTEM WITH HELIX® HELICAL VORTEX GUN

General point

A cleaning system using dry and wet micro-air-abrasion IBIX® equipment with controlled low pressure projection of specific calcium carbonate based aggregates for cleaning artistic artefacts, of extremely fine grain size (from 120 to 350 Mesh) and hardness less than 3 Mohs, or spherical almandine garnet (hardness 7.5 Mohs,) or vegetal blasting materials, or with sodium bicarbonate for non porous, scratchable, and glossy surfaces; hardness to be selected on the basis of the type of substrate and form of degradation being treated.

Operating pressure using compressed cooled and dehumidified air adjustable starting from 0.2 bar.

Micrometric adjustment of the compressed air/aggregate/vaporized water mixture. Light, ergonomic application gun with interchangeable hard metal nozzles and internal aperture of diameters from 1 to 4.5 mm cylindrical or conical, or with helical vortex technology for a HELIX® tangential-rotating abrasive action, particularly recommended for use on decorative elements, friezes, mouldings, and recesses. Distance from the artefact variable on the basis of the surface condition and the operating pressure.